Our 3D metrology service

Component testing

Our 3D metrology service

Component testing

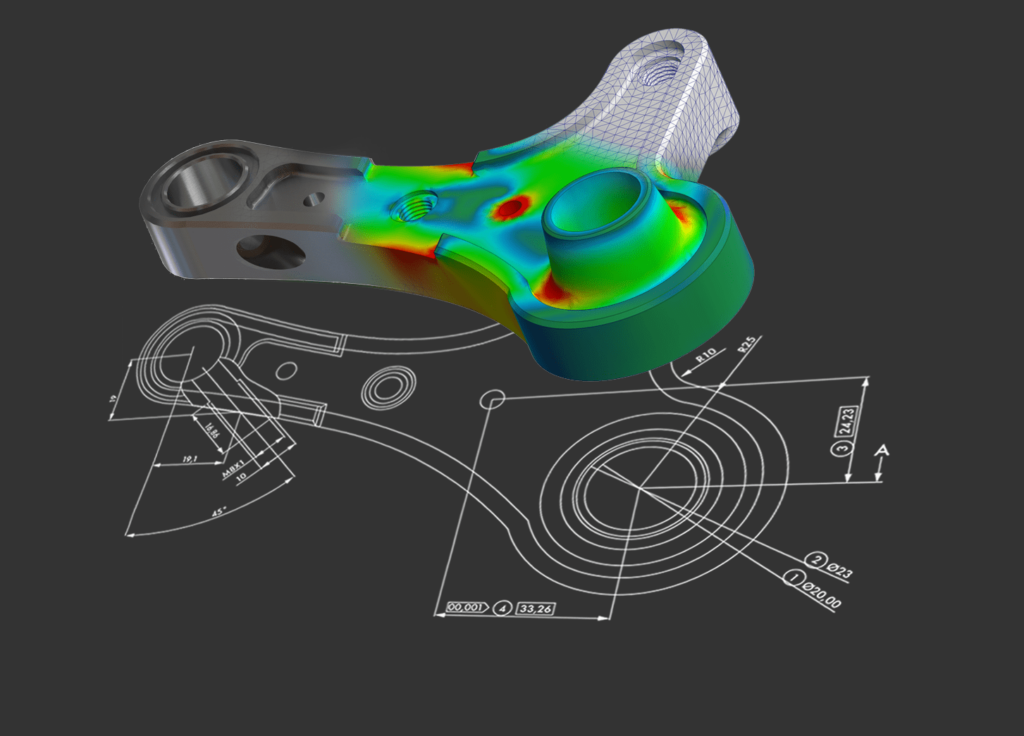

A high-quality form of digitization plays an essential role in optimal object measurement. That is why we work with the precise and flexible 3D scanning systems from GOM. The full-surface measurement data is captured using Blue Light Technology and also enables highly complex components to be scanned. This allows important decisions to be made on product quality.

Evaluations according to

technical drawing

Professional analysis of your technical drawings.

Technical drawings are the starting point for any sampling and a basis for determining which dimensions should be checked. To ensure ideal interaction between different components, we analyze your technical drawings using established GOM brand systems. For identical components, all further analyses can be carried out automatically after an initial evaluation. The alignments and reference systems defined in this way are required for the evaluation of the technical drawing. The final presentation of our analysis will then be sent to you as a report.

Component measurement of initial samples

Quality assurance for flawless series production of your components!

Before series production, all components must be checked in detail to ensure that they function properly. An initial sample test report (EMPB) is used to analyze the quality and product-related specifications of a prototype in order to ensure flawless production later on. A positive test report proves that high-quality series production can be carried out.

Benefit from our measuring capacities!