3D-Metrology: Our service in object measurement

Until recently, 3D scanning of components was an additional service that was used in prototyping or engineering to precisely measure the respective objects. Due to the increasing demand and the variety of applications, this service has become known as “3D metrology” in digitalization. ” has now been established as an independent service at XITEC. In future, our customers will not only have a better overview of all 3D scanning options, but will also be able to have their measurement data determined much more specifically for their respective requirements.

The digital measurement of objects has made enormous progress in recent years. However, precise measurement is not only important for the documentation of objects, but also for decision-making with regard to product quality. A high-quality form of measurement technology plays a decisive role here.

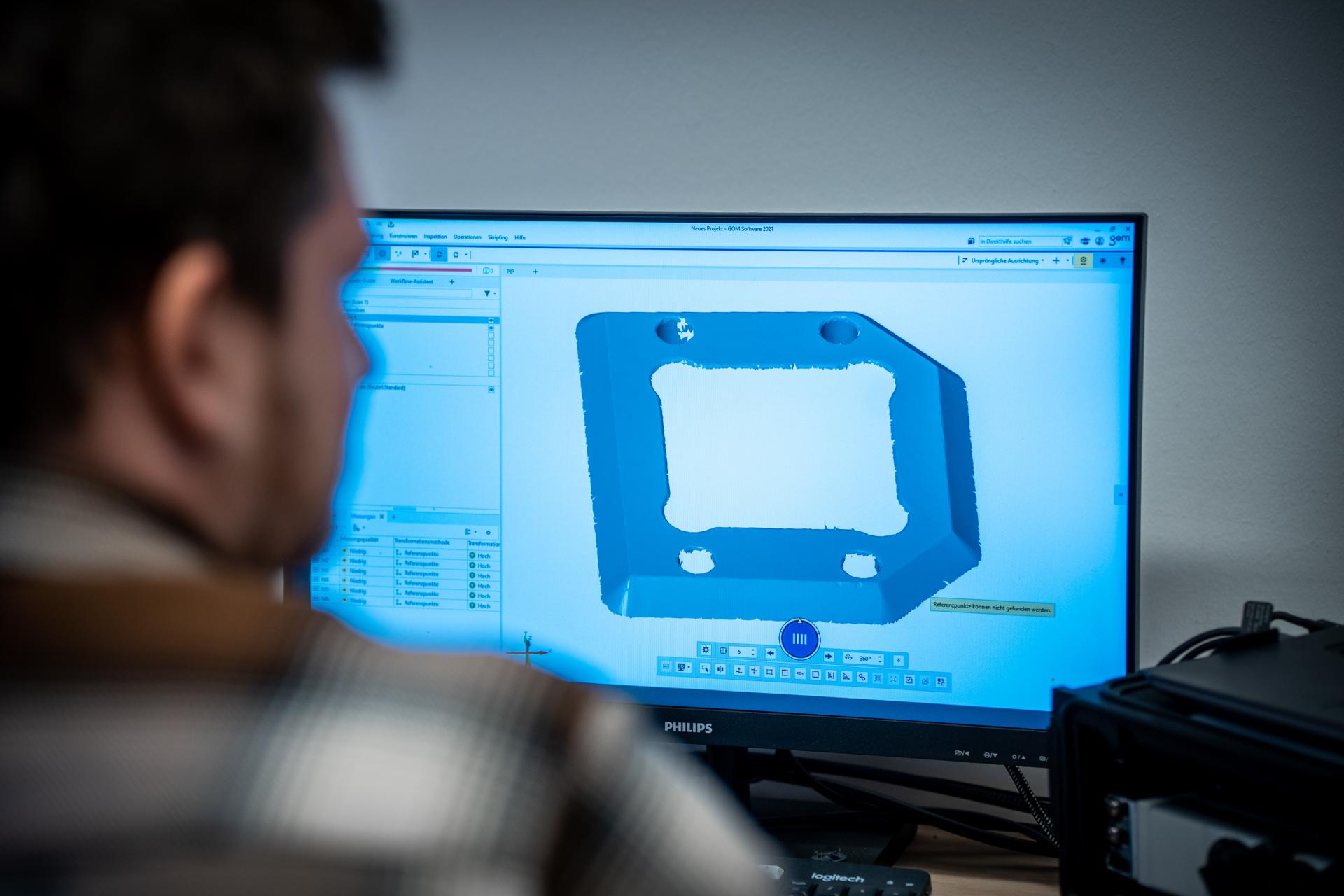

For our component measurements, we rely on the flexible 3D scanning systems of the Zeiss brand, a leading company in the field of digital object measurement. The full-surface measurement data is captured using Blue Light Technology, which also makes it possible to scan highly complex components. The wavelength of the blue light filters out interfering ambient light and ensures high measurement accuracy for components with a wide range of manufacturing technologies such as sheet metal, injection molding, metal casting or 3D printing. A property that is an enormous advantage, especially for complex components with low tolerances. High measurement accuracy avoids costly reworking and ensures optimum quality assurance.

For this all-round measurement of the 3D objects, the components are first provided with reference marks in the form of small, round stickers. The individual scan data can then be aligned in the software using these reference marks and assembled into a digital component. If your components have a surface, we suppress the interfering reflections using a chalk spray to ensure the highest possible measurement accuracy. This method enables us to achieve the best possible measurement quality even with challenging surfaces.

Regardless of whether you want a comprehensive deviation display between the 3D scan and CAD data (surface comparison) or want to go from the object to your 3D scan data (reverse engineering), our experts on site will of course be on hand to advise you and answer your questions about generating and evaluating your measurement data.

Our areas at 3D-Metrology are therefore divided into four services:

- 3D digitization: Making your component digitally available: Fast, high-quality measurement using proven triple scan technology.

- Reverse engineering: From object to precise 3D scan data.

- Component testing: Quality assurance for flawless series production of your components!

- Spare parts service: Ready-to-install wear and spare parts for your needs.

Do you have any questions or would you like a non-binding consultation?

We look forward to your inquiry!